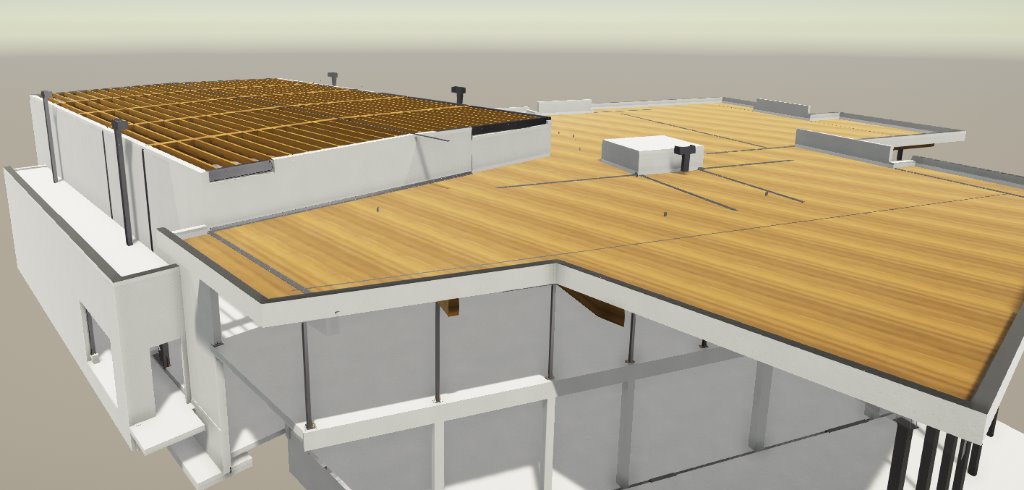

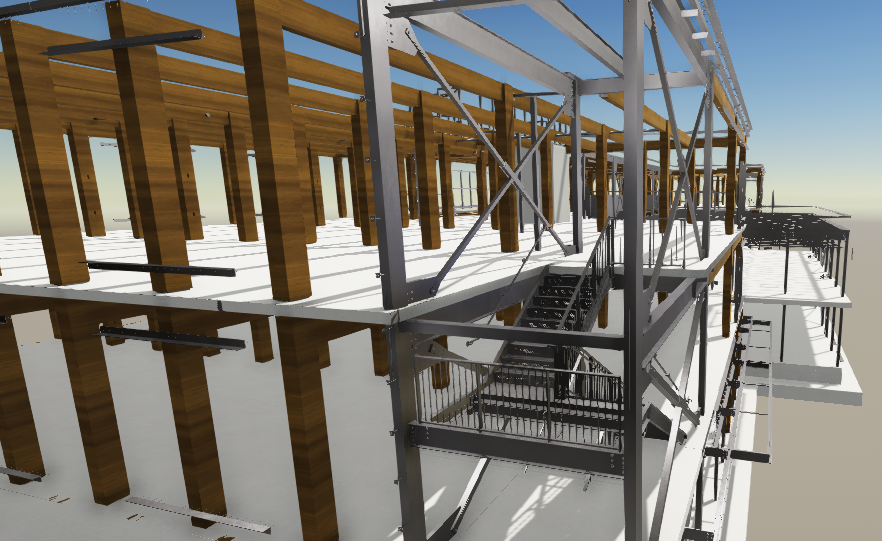

Exact Detailing has supported the Mass Timber production industry since its inception. Our first project began in 2011 on Vancouver Island, and since then, we’ve witnessed—and grown alongside—the industry’s remarkable expansion and evolution. We specialize in 3D modelling, shop drawings, and erection drawings for the production and construction of glulam, CLT, DLT, and other mass timber components. As the industry enters this new phase, we remain committed to engaging with its advancements and evolving alongside it.

With deep expertise in glulam, CLT, and DLT, paired with structural steel proficiency, we ensure seamless coordination between wood and steel in mixed-material projects. Our teams and software scale effortlessly to deliver large, complex projects quickly, while accepting input from nearly any platform (Rhino, IFC, Revit, etc.). We return tailored models and drawings that align with client specifications, including rapid development of custom connections to suit diverse structural needs—all without sacrificing modeling efficiency or quality.

Our predominantly Canadian-based team provides agile support for urgent queries, ensuring minimal downtime. We prioritize safety and accuracy with automated lifting devices generated from real-world COG data. While we avoid proprietary formats like BTL/BVX, our IFC exports integrate smoothly with fabrication tools like Cadworks and HSBCad, empowering partners to generate final NC data efficiently. By bridging timber manufacturers and steel fabricators, we unify design intent with practical execution, streamlining production and construction.